&HER

&HER

(

Private sector

)

#SDGAction51750

Description

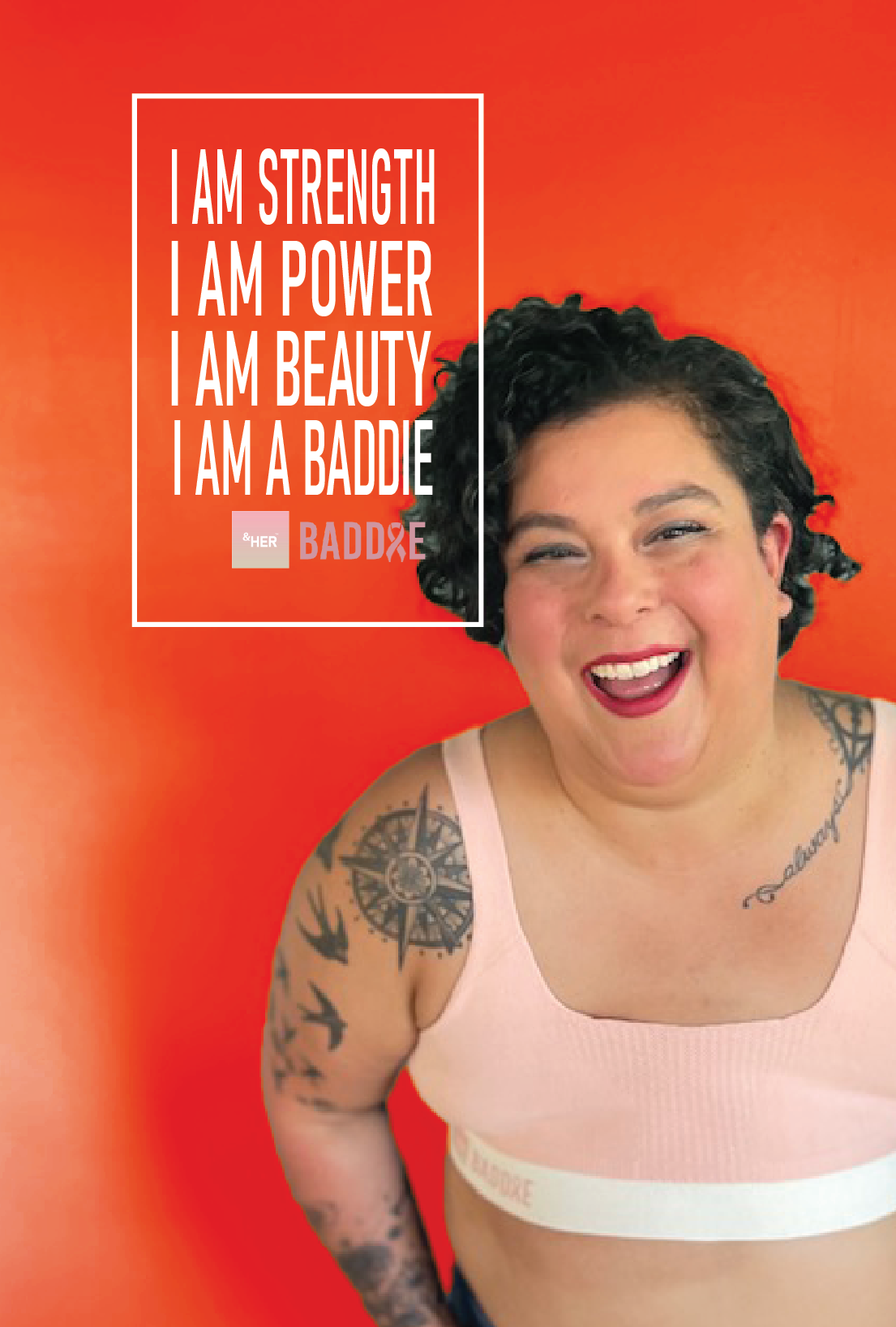

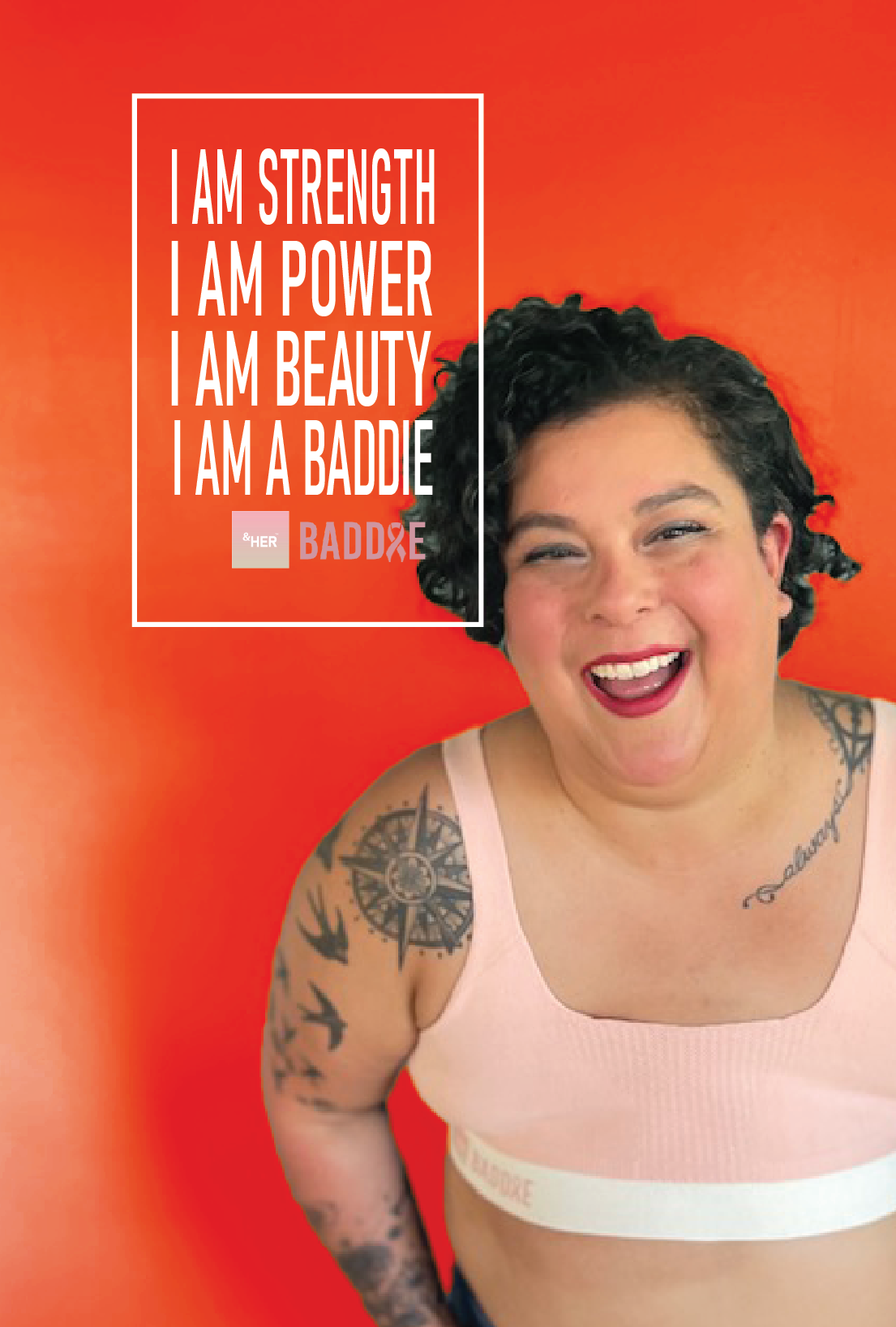

&HER determines measurements and fit via AI Machine Vision and brings data directly to production, so we can manufacture bras customized to each body shape.

There are three main development efforts. First is developing garments using carefully sourced degradable materials to replace synthetic intimate bras and sports bras. Second is a digital product to recognize body shape and measurements using AI machine learning models. And the third is our platform to connect the customer data generated by AI directly to manufacturers to produce personalized garments.

The digital fit harvest solution is fast, cloud-based, and the manufacturing is low waste and automated. We believe the digital fit solution will allow true inclusivity in the fashion industry, customization and on-demand production will reduce inventory waste, and automated additive garment production will further reduce the production calendar.

Firstly, &HER has set up a development studio to refine the automated additive manufacturing process. Second, we will gather data and refine the Machine Vision platform. And lastly, we will launch a browser app to connect consumers directly to customization production.

During each development process, we collaborate with breast cancer survivors and yoga practitioners to test, learn, and improve quickly.

We are also working with bra recyclers to take steps towards circularity within the &HER product life cycle.

During initial developments, we work with individuals as well as small organizations to constantly test the process and products. Capacity building will be gradual when we scale to larger groups once we reach a satisfactory evaluation with the current cohorts.

Once the product is completed and tested, we would be able to invite other enterprises to use our platform to help them understand their customers' fit and reduce inventory waste.

&HER harvests our own data with explicit consent from our participants. We source body types as diverse as possible to train the AI model. By focusing on diversity and inclusivity as the foundation of our product, we believe our platform will improve accuracy in fit prediction.

We are also actively sourcing new regenerative fibers, next generation textile recycling technology, and advanced composting facilities to reduce our carbon footprint and finding a path to circularity

In early stage assessment, we predict the &HER platform will reduce regular apparel product development calendar from 9 months to 3 months, reduce inventory waste by 70%, and move towards circularity by offering a 100% degradable product.

We also have established a constant and open feedback loop with collaborators and testing cohorts to create systematic evaluation, learning, and improvement steps.

The Bra Recyclers, For the Breast of Us, EZAI, and individual yoga practitioners.

SDGS & Targets

Goal 9

Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation

9.1

9.1.1

Proportion of the rural population who live within 2 km of an all-season road

9.1.2

Passenger and freight volumes, by mode of transport

9.2

Promote inclusive and sustainable industrialization and, by 2030, significantly raise industry’s share of employment and gross domestic product, in line with national circumstances, and double its share in least developed countries

9.2.1

Manufacturing value added as a proportion of GDP and per capita

9.2.2

Manufacturing employment as a proportion of total employment

9.3

9.3.1

Proportion of small-scale industries in total industry value added

9.3.2

Proportion of small-scale industries with a loan or line of credit

9.4

By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities

9.4.1

CO2 emission per unit of value added

9.5

9.5.1

Research and development expenditure as a proportion of GDP

9.5.2

Researchers (in full-time equivalent) per million inhabitants

9.a

9.a.1

Total official international support (official development assistance plus other official flows) to infrastructure

9.b

9.b.1

Proportion of medium and high-tech industry value added in total value added

9.c

Significantly increase access to information and communications technology and strive to provide universal and affordable access to the Internet in least developed countries by 2020

9.c.1

Proportion of population covered by a mobile network, by technology

Goal 12

Ensure sustainable consumption and production patterns

12.1

Implement the 10-Year Framework of Programmes on Sustainable Consumption and Production Patterns, all countries taking action, with developed countries taking the lead, taking into account the development and capabilities of developing countries

12.1.1

Number of countries developing, adopting or implementing policy instruments aimed at supporting the shift to sustainable consumption and production

12.2

By 2030, achieve the sustainable management and efficient use of natural resources

12.2.1

Material footprint, material footprint per capita, and material footprint per GDP

12.2.2

Domestic material consumption, domestic material consumption per capita, and domestic material consumption per GDP

12.3

By 2030, halve per capita global food waste at the retail and consumer levels and reduce food losses along production and supply chains, including post-harvest losses

12.3.1

(a) Food loss index and (b) food waste index

12.4

By 2020, achieve the environmentally sound management of chemicals and all wastes throughout their life cycle, in accordance with agreed international frameworks, and significantly reduce their release to air, water and soil in order to minimize their adverse impacts on human health and the environment

12.4.1

12.4.2

(a) Hazardous waste generated per capita; and (b) proportion of hazardous waste treated, by type of treatment

12.5

By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse

12.5.1

National recycling rate, tons of material recycled

12.6

Encourage companies, especially large and transnational companies, to adopt sustainable practices and to integrate sustainability information into their reporting cycle

12.6.1

12.7

Promote public procurement practices that are sustainable, in accordance with national policies and priorities

12.7.1

Number of countries implementing sustainable public procurement policies and action plans

12.8

By 2030, ensure that people everywhere have the relevant information and awareness for sustainable development and lifestyles in harmony with nature

12.8.1

Extent to which (i) global citizenship education and (ii) education for sustainable development are mainstreamed in (a) national education policies; (b) curricula; (c) teacher education; and (d) student assessment

12.a

Support developing countries to strengthen their scientific and technological capacity to move towards more sustainable patterns of consumption and production

12.a.1

Installed renewable energy-generating capacity in developing and developed countries (in watts per capita)

12.b

Develop and implement tools to monitor sustainable development impacts for sustainable tourism that creates jobs and promotes local culture and products

12.b.1

Implementation of standard accounting tools to monitor the economic and environmental aspects of tourism sustainability

12.c

Rationalize inefficient fossil-fuel subsidies that encourage wasteful consumption by removing market distortions, in accordance with national circumstances, including by restructuring taxation and phasing out those harmful subsidies, where they exist, to reflect their environmental impacts, taking fully into account the specific needs and conditions of developing countries and minimizing the possible adverse impacts on their development in a manner that protects the poor and the affected communities

12.c.1

Amount of fossil-fuel subsidies (production and consumption) per unit of GDP

SDG 14 targets covered

| Name | Description |

|---|

Deliverables & Timeline

Launch automated manufacturing studio

AI Model Completion

Web Browser Launch

Resources mobilized

Partnership Progress

Feedback

Action Network

Timeline

Entity

Region

- North America

Geographical coverage

Other beneficiaries

Consumers, manufactures, and retailers.

&HER can offer better fitting garments to the consumer, reduced inventory and returns for the retailers, and shorten development calendar to the manufacturers.

Today, it is hard for the consumer to find synchronized sizing from brand to brand, and with &HER, customers will get a custom fitted garment in every stage of their womanhood: puberty, maturity, pregnancy, and nursing. For retailers, having better prediction to the customer sizing can reduce inventory on hand, warehousing cost, and save on less returns. Manufacturers can also save capital from the shortened product development timeline.

&HER’s shortened supply chain will allow for transparency in consumption (consumers will know exactly what fiber went into their product), waste management (we know every fiber placed in each part of the garment for easy recycling), and pave a path to a circular product cycle.

Photos

More information

Countries

Contact Information

Nini Hu, Founder