Biodiversity recovery of a coastal seaweed bed by using the Vivary Unit composed of steelmaking slag, by-product of steel manufacturing

Description

NSSMC has developed the Vivary Unit, a fertilizer that supplies iron compound in the seawater, and has installed it on the sea floor where it can promote growth of seaweed. Slag and humus-rich soil, its major components, are recycled materials which are readily sourced at low cost. The first installation was made in 2004 in Mashike Town, Hokkaido, where the seabed desertification had caused a decline in the fishery. By 2014, 42 tons of the Vivary Unit were installed and helped recover 1.3 hectare of seaweed beds, contributing to restoration of biodiversity and revival of the fishery.

The Vivary Unit is a fertilizer developed for helping to prevent loss of functioning seaweed beds, a phenomenon known as “sea desertification,” observedin the coasts of various parts of Japan. Focusing on the iron deficiency in the seawater, which is considered to be one cause of sea desertification, we postulated that the supply of iron contained in steelmaking slag – a by-product of iron and steel manufacture – could help seaweed beds to recover. Our experiments have validated the effects. As supply of iron in the seawater and use of steelmaking slag for this were unprecedented, we had to make various attempts, steadily accumulate results, and make persistent efforts in order to achieve viable results. The Vivary Unit is a mixture of steelmaking slag and humus-rich soil, which supplies iron, an indispensable material needed for healthy seaweed growth, in the form of dissolved ions, to the seawater. The iron ion originates in the steelmaking slag and is eluted by the organic acids from the humus soil. NSSMC generates approximately 5 million tons of steelmaking slag every year, at the ratio of about 110 kg of the slag being generated as a by-product from manufacturing of one ton of iron and steel, while the humus soil is obtained by fermentation of waste wood chips. As both the slag and the enriched soil are recycled materials, they are easily and reliably sourced at low cost. [12.2/14.2] The seaweed bed created by placing the Vivary Unit on the sea floor can also be a promising contributor to improvement of the blue carbon ecosystem. Recently, much attention has been given to sequestering carbon in coastal ecosystems, or blue carbon. Maintenance and expansion of the seaweed beds created by use of the Vivary Unit, and its application to other marine areas, can be considered as a way to increase sequestering. As an additional possibility, use of the Vivary Unit may dampen the impact of ocean waves driven by tsunami, as coastal seaweed beds contribute to significantly damp offshore waves. Their effects can be boosted by installing the Vivary Unit along coast lines, which should eventually demonstrate the similar function to gray infrastructure including breakwater. [13.1] When Japan’s Fisheries Agency was revising the “Guideline on Measures Against Sea Desertification,” we conducted an experiment to validate the effects of the Vivary Unit, jointly with the Agency. The results were referenced on the revision, and helped raise awareness of this new iron fertilizing technology. Moreover, the Blue Carbon Study Group, which reports to the Ministry of Land, Infrastructure, Travel and Tourism, is studying the measurement and analysis of the sequestering, in preparation for future estimation of the potential of blue carbon. In line with such moves, we are continuing our project so that the artificial seaweed beds by use of the Vivary Unit can make a similar contribution to the ecosystem as the natural seaweed beds do. [13.2]

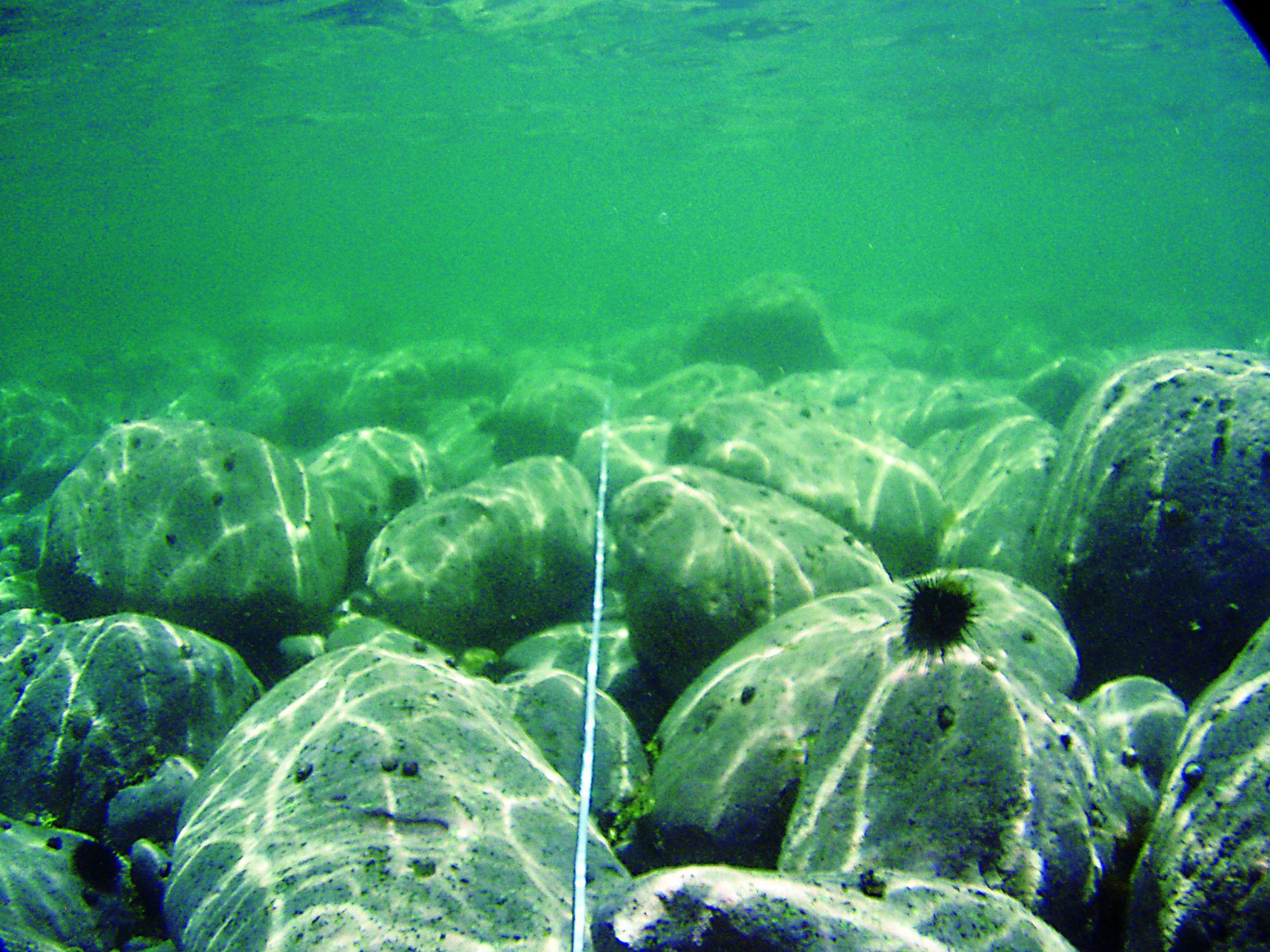

The experiment in Mashike has been conducted in two phases. Phase I (2004-2014) was to develop and install the Vivary Unit in the actual sea floor for the first time, and validate its effects. Phase II (from 2014) began as a large-scale experiment with the aim of assessing the economic impact of creation of seaweed beds. Phase I experiment was sponsored by the Sea Forestation Study Group. This group, which is comprised of experts in areas such as civil engineering and biology, and from industry and academia (including those from the University of Tokyo, Hokkaido University, Nishimatsu Construction, Penta-Ocean Construction, and NSSMC and others), was established with the aim of validating the seaweed bed creation technology by use of the Vivary Unit, and has been testing the installation method and the quantitative assessment method for this. For Phase I, the test site selected was in Shaguma, Mashike Town, and was provided by the cooperative. The Vivary Unit was embedded in the seabed by NSSMC. The Shaguma site, having stones in the seabed and primarily being shoals of 3-4 meters in depth and about 100 meters in length, was ideal for sea forest creation. Six tons of the Vivary Unit were placed along 25 meters of the shoreline. The installation method aimed at the outflow of the water (containing iron ions) from the Vivary Unit, to be caused by the rise and fall of the tide. According to the research conducted by the study group before the placement of the Vivary Unit, conditions at this test site were typical of sea desertification. The site was covered with white stones with dead coralline algae (Corallinales), with exception of some kelp (Saccharina japonica) being scattered around (Photo 1, as of September 2004). Based on the results of Phase I, Phase II was begun in 2014 as a large-scale undertaking aimed at assessing the economic impact of creation of seaweed beds. It has been implemented by the Mashike cooperative. A second test site in Betsukari, Mashike Town was selected by the cooperative; this choice was made mainly because the site was not used for fishery and was also shoals with seabed stones, similar to Shaguma. NSSMC installed 36 tons of the Vivary Unit along the shorelines, by using the same placement method as before. The test site was six times larger than the Phase I site. It consisted of six sections with each section being 50 meters in length. Six tons of the Vivary Unit were placed in a 25-meter line, or half of the section length. In order to assess economic impact of seaweed bed creation, the sea urchin was selected as the fishery product to test as it likes to eat a certain edible kepl and the urchin is a valuable product harvested at the local port. The Sea Forestation Study Group has been engaged in research on water quality and seaweed beds after the Vivary Unit placement, and has been participating in discussions with the cooperative on yields of the sea urchin.

NSSMC has developed the Vivary Unit and has used it to create seaweed beds. The Vivary Unit is composed of steelmaking slag, which is a by-product of steel manufacture, and humus-rich soil made by combining fermented waste wood chips with soil. Both the slag and the humus soil are recycled materials that can be reliably generated and purchased at low cost. As supply of iron in the seawater and use of steelmaking slag for this were unprecedented, we initially had to make persistent efforts to be acknowledged. For the first adoption of the Vivary Unit in the ocean in Mashike Town, Hokkaido, first of all, a sea forestation study group was established by experts in industry and academia for objective research and development of installation methodology. We also strengthened the cooperative relationship with fishermen and local people concerned and jointly conducted an experiment so that the unprecedented adoption of steelmaking slag in a marine area could be accepted in the community. As a result, the demonstration experiment was stepped up from Phase I to Phase II and made considerable achievements. The Vivary Unit installation has led to a rise in the iron content in the seawater, a creation of 1.3 hectares of seaweed beds, and a 1.8 times increase in the yield of sea urchin, and proved positive effects for fisheries. With the aim of widely promoting the Vivary Unit, scientific papers on the mechanism of the effects and the results of the demonstration experiments have been published (including 19 papers with peer review) and scientific evidence has been accumulated. Moreover, we promoted the effects of the Vivary Unit at exhibitions and through site visits, as well as in the in-house mesocosm aquaria tests. Jointly with Japan’s Fisheries Agency, we conducted the experiment and the seaweed bed creation technology was referenced in the “Guideline on Measures Against Sea Desertification.” In order to assure safety, we conducted a 96-hour acute toxicity test by exposing three kinds of valuable marine products to the eluent of the Vivary Unit. The test result was examined by a third-party institution and the Vivary Unit received the approval of the National Federation of Fisheries Cooperative Associations. By accumulating such objective insights, the Vivary Unit has become better recognized and the number of its installed sites has increased to 37 sites across Japan. Going forward, for further penetration of the seaweed bed creation technology by use of the Vivary Unit and a resultant decrease in the desertified sea areas across Japan, a wider expansion of the present undertaking alone is not enough. Other indispensable elements are a cooperative network among business operators, local fishermen and authorities, and proactive initiatives by local people who use the developed site. We sincerely hope the national and prefectural governments will establish a support system for such initiatives. The revived seaweed bed is also promising as a blue carbon ecosystem. Going forward, we plan to continue the project and accumulate scientific evidence on the evaluation method and the effects of carbon sequestering.

SDGS & Targets

Deliverables & Timeline

Resources mobilized

Partnership Progress

| Name | Description |

|---|---|

| 14.2 | By 2020, sustainably manage and protect marine and coastal ecosystems to avoid significant adverse impacts, including by strengthening their resilience, and take action for their restoration in order to achieve healthy and productive oceans |

Feedback

Action Network

Timeline

Entity

Region

- Asia and Pacific

Geographical coverage

Photos

Website/More information

Countries

Contact Information

Hisayuki Hayashi, Environmental Relations Dept. Environment Div.